this post was submitted on 27 Sep 2024

539 points (96.9% liked)

Memes

45719 readers

1057 users here now

Rules:

- Be civil and nice.

- Try not to excessively repost, as a rule of thumb, wait at least 2 months to do it if you have to.

founded 5 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

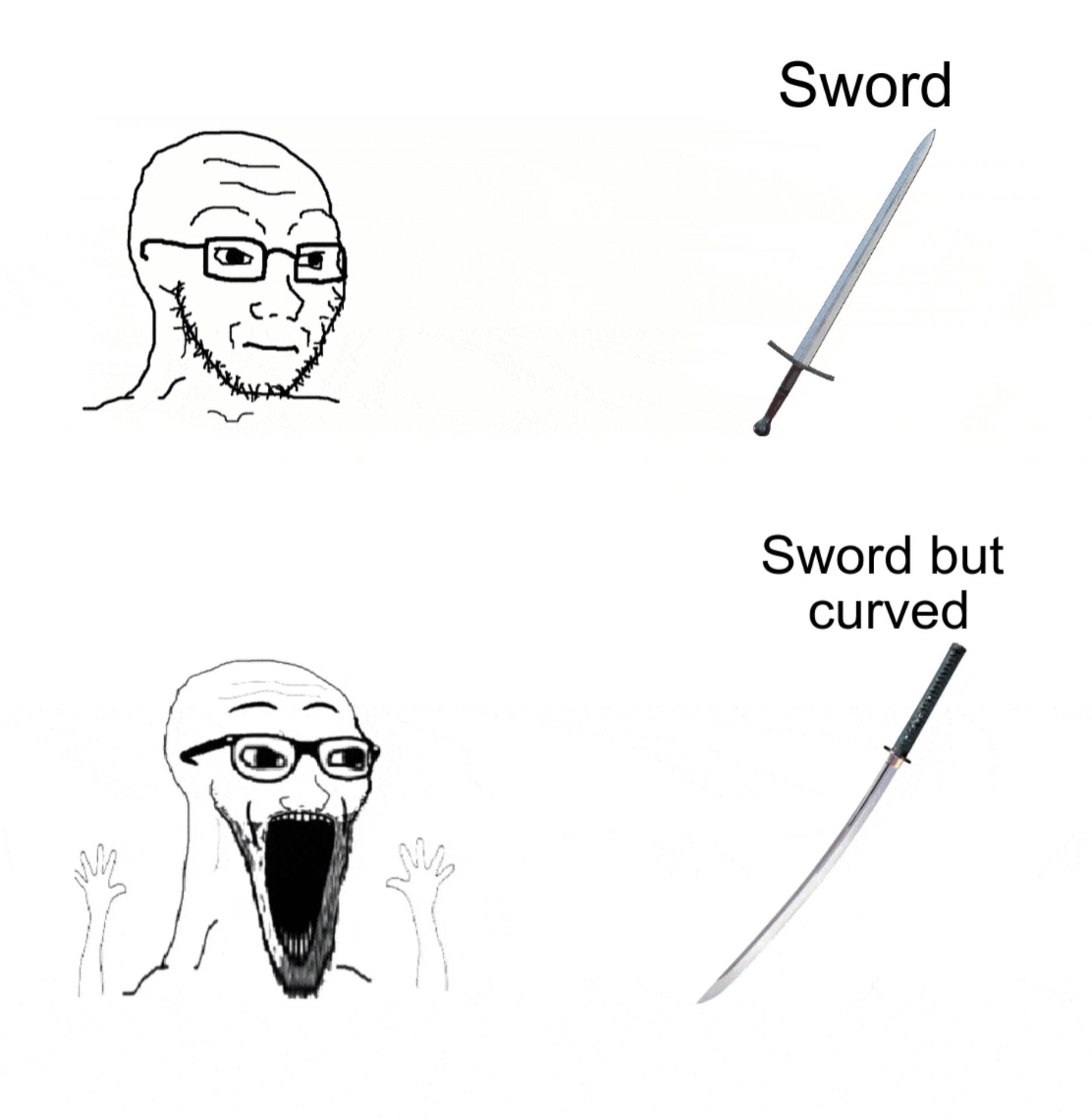

While you were out there whacking your straight stick, I spent years studying the blade...

The whole "Japanese steel was really weak" thing is as much of a myth as the whole "katanas are super powerful superior weapons" thing.

They're all just swords, and don't make that much of a difference either way.

Katana's are weak on the flat side. They aren't really meant to be used for parrying. In fact, most sword fights in Japan would be over after the first or second swing. It was commonplace to hold the grip of a katana but not draw it in such a way so that your enemy has trouble judging how long your katana is and what is a safe distance to be from you. Once your opponent is in range, draw it quickly and kill them in one blow, ideally.

The act of killing your opponent in a single blow is called "nukitsuke" from "nukiuchi" meaning "to cut down an opponent" and "tsuke" meaning "to stop an opponent's attack before it begins".

The Sekiro and popular media image of extended katana fights didn't really happen, but if they did, there would almost certainly be some broken katanas.

I promise you, in the real world, fights were just as much of a shield shoving match while trying to slash your opponents ankle as they were in Europe.

The idea of a one-on-one sword fight decided by individual skill is much more of a romantic idea.

lolwut? Try that leg-targetting shit with a HEMA fighter and see how fast you'll bleed out.

HEMA is not combat. It's tournament fighting. In combat you've got a thousand spearmen on either side looking to stick you with a sharp stick wherever they can.

I imagine it like a hockey match where when a stick breaks they just go get another one and continue on like nothing happened

According to the dictionary, 抜き打ちnukiuchi and 抜き付けnukitsuke sound like synonyms. I'm a little confused.

I guess with uchi (to strike down) vs tsuke (to put, attach, etc) one sounds more like the result and the action but it's weird that the definitions from Jisho.org aren't too explicit.

I think because "nukiuchi" would be pronounced like "NOO-KEE-OO-CHEE" and "nukitsuke" would be pronounced like "NOO-KEE-SOO-KEE" so kind of similar. I dunno though!

According to whom?

The reason why Japanese iron is inferior is because of the source of the iron itself, they utilized iron sand instead of rock ore. Rock ore can be made up to 90% ferrous material while the iron sand contains as little as 2%.

This means when you smelt your source material into blooms of iron and slag, the blooms made from sand iron were much smaller. Instead of utilizing a single bloom to make a sword, the Japanese had to work several blooms together. Which is much more labour intensive, and can lead to a lot of imperfections in the final product.

This is why katanas were made out of so little material, and had to be handled with care. They were much more fragile pieces than similar swords made in Korea and China at the time.

Plus, the Japanese developed their iron working much later than their mainland contemporaries, as they never independently invented furnace technology. The technology for furnaces was imported, most likely from the Korean peninsula.

There's also smelting. Japan didn't have the technology to completely melt iron, which complicates things.

What century of katana are you speaking about? Many katana were used with modern metallurgy technology and imported steel. Do you think modern Japanese created cars are also made from steel refined from sand? Do you think the guns Japanese Samurai used were made from steel refined from sand?

Lol, my dude. No one is claiming that modern japanese steel is of poor quality.

Im speaking of the time period contemporary with the accusation. You know, how arguments typically work......

Just pointing out this one because it's funny. Yes, a lot of the early firearms made in Japan were still made from iron sand (Satetsu). Which was the main source of iron in Japan until the 16th century.

There was nothing inherently low quality about using iron sand anyway. Impurities were carried away by slag and the iron in the sand was easily recovered using washing and later electromagnetism. Imports were used as demand increased.

You are conflating the elemental molecule of iron with the finished product of an alloy of carbonized iron aka as steel.

Yes, there isn't a molecular difference between the iron found in sand vs the iron found in rock ore. However, the medium in which you harvest your iron and how you're able to heat that iron, dictates the quality not your final product.

The truth is that the steel made from Iron Sand was not lower quality than the Steel made from other sources of Iron.

That's not true, no matter how many times you make that unsupported claim.

Holy shit you're wrong, now with references

https://gunbai-militaryhistory.blogspot.com/2018/02/iron-and-steel-technology-in-japanese.html

My dude, nothing in that blog supports your claim.

First of all, it's talking about the metallurgy of the 16th century and after, which is after Japan had imported blast furnaces. Secondly, it ignores the amount of labour needed to actually produce refined steel from iron sands, which ultimately dictates the quality of the finished product.

This isnt a debatable topic, any steel made from iron sands before modern electromagnetic sorting contains a large amount of impurities when compared to steel made from rock ore.

Even during WW2 the Japanese had a hard time producing high quality steel even with the use of blast furnaces, because the iron sands contains a large amount of titanium.

This blog which falls over itself trying to engage in revisionist history, can only claim that the quality was "perfectly fine"....not good.

You've proven yourself wrong.

Mochi Tetsu is mentioned in that article as being a source that produces higher quality products than iron sand. Exactly what you're arguing against.

The facts are that due to the limited availability of good quality iron ore the steel produced in Japan often used iron sand and that led to lower quality products.

Yeah, Japanese steel wasn’t great, but they were working with what they had available at the time. Katanas were basically made out of iron dust, which had been melted into slag by filtering through charcoal. The resulting chunks of steel were basically straight up slag, not nice even ingots. So the steel they got was actually extremely high carbon in places, but that also meant it was brittle as hell, because those carbon pockets were prone to shattering.

So the folding was invented, to even out the steel’s carbon content (just like how a Damascus steel blade has visible stripes, Japanese steel had invisible stripes of high and low carbon steel) and to lower the carbon content overall; Every time you heat for another fold, you’re evaporating some carbon. So the folding process took the steel from extremely high carbon pockets to a more evenly distributed carbon content.

Now that modern steel processing exists, the only real reason to stick to the folding method is tradition. There’s no need to fold modern steel ingots because they’re already homogenous and can be produced at whatever carbon level you want.

Impurities are melted into slag. Not the iron. That's what slag is.

And looks. Those folding create a wavy pattern on the blade which is desirable feature for collector.

If you’re referring to the wavy pattern along the cutting edge, that’s not from the folding process. The hamon is added to the blade during the quenching process, by adding clay to the steel. The clay causes the covered steel to heat differently than the uncovered steel. That differential heating is what is visible as the hamon.

It’s largely decorative, but does have function as it determines what part of the blade can be sharpened to an edge.

There is still benefit to hot forging the steel to refine and align the microstructure, but it doesn’t have to be many folds.

Yeah they're a bit better at slashing whilst a straight sword is slightly better at thrusting. Typically a curved sword is a bit better whilst on horseback or whilst fighting unarmoured or lightly armoured opponents and straight blades are a bit better whilst fighting one-on-one and against somewhat more armoured opponents.

But these are slight differences and sword styles are also varied in each region, so the Japanese did develop swords which were more adapted to thrusting with reinforced tips and Europeans did develop swords which were more effective at slashing.

I think some people obsess over what swords are the best and the worst. In reality the style of sword was unlikely to be the major deciding factor in a one on one fight. The amount and quality of armour and the skill and capacity (Size and strength) of the fighters themselves are much bigger factors.